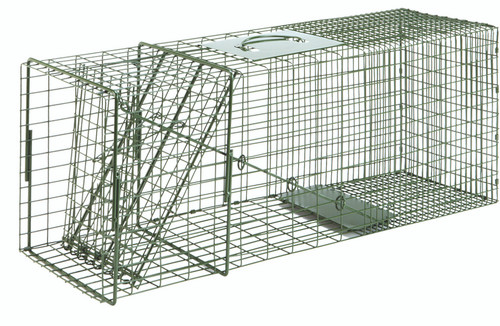

Description

Animal traps provide a humane way to get rid of your problems with nuisance animals. This trap is built with the medium to large sized animal in mind like a raccoon. The trap is fully assembled and easy to bait and set.Heavy Duty Model is made of 14 Gauge wire that is strong enough a man can stand on it and it will not bend. Bait protected 1/2" Mesh. Welded Rod reinforced gravity door with locking rings. 1/4" Reinforced Rod Frame.

Easy release by just turning the trap completely over so door releases and animal can run out without you having to get to close to trap while the animal is inside. Epoxy Coated GREEN. Size: 28" x 12" x 12"

Product Videos

Videos Hide Videos Show Videos

Product Reviews

Custom Field

ey-video

yahoo-id duke-animal-trap--large-heavy-duty